Search This Supplers Products:Magnesium SulphateMagnesium OxideAmmonium SulphateZinc SulphateFerrous SulphatePotassium Sulphate

Caustic Calcined Magnesite Magnesium Oxide Briquette

- group name

- Magnesium Oxide

- Min Order

- 20 metric ton

- brand name

- Richase Magnesium Oxide Supplier

- model

- Briquette

- Nearest port for product export

- Dalian, Qingdao, Tianjin, Huangpu

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash

- update time

- Fri, 27 Feb 2026 14:39:57 GMT

Paramtents

Color Off-White

Other Name Briquette

Chemical formula MgO

Molecular weight 40.3044

CAS No. 1309-48-4

Density 3.58 g/cm3(25℃)

Appearance Off-white briquette

Water soluble 6.2 mg/L (0℃)

Melting point 2,852℃ (5,166 °F; 3,125 K)

Packing PP+PE 1000/1250kg

Loading Port Dalian

Certificate ISO, SGS, CIQ, CCIC, Intertek

Terms of Payment T/T, L/C, Western Union, MoneyGram, Paypal

Packging & Delivery

-

Min Order20 metric ton

Briefing

Detailed

Product Description:

Magnesium oxide (MgO), or magnesia, is a white hygroscopic solid mineral that occurs naturally as periclase and is a source of magnesium (see also oxide). It has an empirical formula of MgO and consists of a lattice of Mg2+ ions and O2− ions held together by ionic bonding. Magnesium hydroxide forms in the presence of water (MgO + H2O → Mg(OH)2), but it can be reversed by heating it to separate moisture.

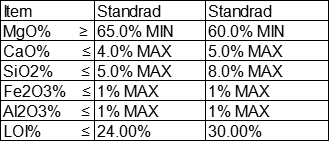

Specification:

Benefits:

Packaging & Storage:

2. To be stored in cool, dry and ventilated place,